Equipment

4 Best Welding Boots for Beginners [Comparison Table]

Welding is a demanding job that requires proper protective gear to ensure the safety and comfort of the welder.

One of the most important pieces of protective gear for a welder is a pair of welding boots. Welding boots protect the feet from heat, sparks and other hazards associated with welding.

With so many options on the market it can be difficult for beginners to choose the best welding boots for their needs.

In this blog, we will provide a comparison table of the 4 best welding boots for beginners to help make your decision easier.

Summary:

| Boot | Material | Heat Resistant | Slip Resistant | Steel Toes | Comfort | Durability |

|---|---|---|---|---|---|---|

| Timberland PRO | ? Leather & rubber | ? Moderate | ? Good | ? No | ? Good | ? Good |

| Dr Martens Industry | ? Leather | ? Bad | ? Good | ? No | ? Moderate | ?Moderate |

| Skechers Industrial | ? Leather & synthetic | ? Good | ? Good | ? No | ? Good | ? Good |

| Iron Age Ground Breaker | ? Leather | ? Bad | ? Good | ? Yes | ? Moderate | ? Moderate |

Features to Consider When Buying Boots for Welding

1- Material: Go with leather boots or shoes, and make sure they come up high on your ankle. Leather is the best option because it protects you from the hazards and heat created by the welding process. The tops of the shoes should be smooth so sparks don’t get trapped.

2- Heat resistance: Welding can produce extreme temperatures and sparks. So it’s important to choose a welding safety shoe that can withstand these conditions.

Look for shoes that are made of materials that are heat resistant. Such as leather or synthetic materials and have reinforced toes and soles.

3- Slip resistance: Welding often takes place on slippery surfaces. Therefore it’s important to choose a shoe that has a slip-resistant sole.

Look for shoes that have a non-slip sole made of rubber or other slip-resistant materials.

4- Steel toes: Many welding safety shoes come with steel toes to protect the feet from falling objects and other hazards.

Steel toes are typically required by OSHA (Occupational Safety and Health Administration) for welding safety shoes.

5- Comfort and fit: Welding can be a physically demanding job and it’s important to choose a shoe that is comfortable to wear for long periods of time.

Look for shoes that have padded insoles and good arch support.

6- Durability: Welding safety shoes are often subjected to harsh conditions therefore it’s important to choose a shoe that is durable and can withstand the wear and tear of welding.

Look for shoes that are made of sturdy materials and have reinforced toes and soles.

7- Additional features: Some welding safety shoes come with additional features such as electrical hazard protection, puncture-resistant sole and waterproofing.

It’s important to consider these features if you are working in an environment with electrical hazards or wet conditions.

Our Top 4 Picks

- Timberland PRO

- Dr Martens Industry Boots

- Skechers Industrial Boot

- Iron Age Ground Breaker Work Boot

1- Timberland PRO

The Timberland PRO is an exceptional work boot made with premium materials such as ever guard leather and rubber toe protectors for durable performance on the job site.

With a TPU outsole featuring deep lugs the Timberland PRO provides excellent traction, slip resistance, oil resistance and abrasion resistance. Ensuring your safety in any conditions.

The anti-fatigue technology with shock-absorbing geometrical design provides all-day support and comfort. While the 400 grams of insulation makes these boots ideal for winter wear. The Timberland PRO is crafted with a tradition of craftsmanship and innovation resulting in a work boot that is built to last.

Key Features

1- Material: Made with Ever-Guard leather and rubber toe protectors for abrasion-resistant performance

2- Outsole: TPU outsole with deep lugs for traction, slip, oil, and abrasion resistance

3- Comfort technology: Anti-fatigue technology with shock-absorbing, geometrical technology that returns energy back to the foot for all-day support and comfort

4- Craftsmanship: Built on a tradition of craftsmanship and innovation

5- Durability: Timberland PRO footwear styles stand up to the rigors of the worksite with built-in comfort technologies, electrical hazard protection and slip-and-oil resistant soles

6- Sizes available: Available in 6-inch and 8-inch options

7- Insulation: 400 grams of insulation for winter wear.

| Feature | Description |

|---|---|

| Material | Leather and rubber |

| Heat resistance | Not mentioned |

| Slip resistance | TPU outsole with deep lugs for slip, oil, and abrasion resistance |

| Steel toes | Not mentioned |

| Comfort and fit | Anti-fatigue technology with shock-absorbing, geometrical technology that returns energy back to the foot for all-day support and comfort |

| Durability | Ever-Guard leather and rubber toe protectors for abrasion-resistant performance |

| Additional features | 400 grams of insulation for winter wear, available in 6-inch and 8-inch options, electrical hazard protection, slip-and-oil resistant soles, polyurethane midsole. |

The Downsides of Timberland PRO

- May not be long lasting

- Not water proof (first pair)

- May Split at the point where the leather meets the soles

- Top of heel area may start to wear through the first layer of the boot

- Insoles tend to wear out quickly.

2- Dr. Martens Industry Boots

The Dr. Martens 1460 boots are a modern update to the classic design featuring heritage elements such as yellow welt stitching and 8 eyes. The boots have been re-engineered for improved ergonomic comfort with SoftWair sockliners and memory foam footbed.

The boots also have a slip-resistant Grip-Trax sole and water-resistant leather construction making them perfect for workers who are on their feet for long hours.

Key Features

1- Material: Made with industrial, water-resistant leather and synthetic sole

2- Sole: DM’s iconic air-cushioned sole re-engineered with enhanced grip and GRIP-TRAX lug formation

3- Comfort: Breathable SoftWair sockliners with memory foam pods and supportive memory foam footbed

4- Design: Ankle height, 8 eyes, yellow welt stitching, and scripted heel-loop for heritage Docs DNA

5- Additional Features: Padded collar and tongue, anti-fatigue design with extra flex and less weight, and slip-resistant Grip-Trax tread

| Feature | Detail |

|---|---|

| Material | Industrial, water-resistant leather |

| Heat resistance | No |

| Slip resistance | Enhanced grip with Grip-Trax outsole |

| Steel toes | No |

| Comfort and fit | Breathable, moisture-wicking SoftWair sockliners, with memory foam pods and supportive memory foam footbed |

| Durability | Spill-resistant, easily wiped clean |

| Additional features | Anti-fatigue design, extra flex, less weight, grip-trax tread for all workplace surfaces, airflow lining to minimize odor |

The Downsides of Dr. Martens Industrial Boots

- Uncomfortable, digging into feet and may cause bruises

- Poor water resistance, feet may become soaked quickly

- Loud and noticeable popping noise in soles

- Some customers reported that Stitching breaks easily

- Poor durability, some customers reported that soles detached after 5 months of use

- Inconvenient replacement process (on Amazon).

3- Skechers Industrial Boots

These Skechers men’s boots are made of 100% leather and feature a rubber sole. The shaft measures approximately 5.5 inches from the arch and they have a steel toe for added protection. They also have a memory foam insole for added comfort and are rated for electrical hazards.

Key Features

1- Material: 100% leather material is used for the construction of the product.

2- Heat resistance: Boots are not heat resistant.

3- Slip resistance: It has a rubber sole, which offers slip resistance.

4- Steel toes: It features a steel toe, providing added protection for the toes.

5- Comfort and fit: Memory foam is used in the product, providing comfort and a better fit.

6- Additional features: It has an electrical hazard feature, offering additional protection in electrical environments.

| Feature | Description |

|---|---|

| Material | 100% Leather, Imported |

| Heat resistance | Not mentioned |

| Slip resistance | Rubber sole |

| Steel toes | Steel Toe |

| Comfort and fit | Memory Foam |

| Durability | Not mentioned |

| Additional features | Electrical Hazard |

Downsides of Skechers Industrial Boots

- A little high heel

- Sole is hard and stiff to wear all day

- May not fit well for people with thinner ankles

- Some customers report steel toe hits toes, leaving bruises

- Soles not well padded, can become uncomfortable after prolonged wearing

- Not meant for comfort

4- Iron Age Ground Breaker Work Boot

Iron Age Groundbreaker Work Boots are designed tough for construction, landscaping, welding, masonry, electrical work and oil & gas workers.

Made with 100% full grain leather and steel toe construction, these boots meet ASTM F2413 standards and offer electrical hazard protection.

The external met guard provides extra protection against falling objects, chemicals and oils, metal chips and shards, hot surfaces, and uneven surfaces.

With features like Goodyear Welt construction, Kevlar stitching, and a removable EVA cushion footbed, these boots will keep you comfortable and protected all day long.

Key Features

1- Material: 100% leather upper with Goodyear Welt construction and Kevlar stitching. Imported with a manmade sole.

2- Heat resistance: Can withstand hot surfaces.

3- Slip resistance: Rubber lug outsole provides slip resistance on uneven surfaces.

4- Steel toes: Steel toe construction for added protection.

5- Comfort and fit: Shaft measures approximately 6.75″ from arch with a 1.5″ heel and 1″ platform. Lining features Moisture Wicking Nylon Mesh and an EVA Cushion Removable Footbed with a Sponge Rubber Heel Wedge.

6- Durability: Resistant to heavy falling and rolling objects, chemicals and oils, metal chips and shards.

7- Additional features: Meets ASTM F2413 standards for safety footwear, has electrical hazard protection, and an external met guard for protection from dropped objects.

| Feature | Description |

|---|---|

| Material | 100% Leather |

| Heat resistance | Not specified |

| Slip resistance | Not specified |

| Steel toes | Yes |

| Comfort and fit | EVA cushion removable footbed with sponge rubber heel wedge |

| Durability | Goodyear Welt Construction, Kevlar Stitching |

| Additional features | Electrical hazard protection, Moisture-wicking nylon mesh lining, Rubber lug outsole |

Downsides of Iron Age Ground Breaker Work Boot

- Low quality insole.

- Heel box too large.

- Laces wrap around the ankle, making it difficult to tie.

- Eyelets need to be further away from the tongue for better lacing.

- Rough inside back where heel goes.

- Heel is a bit rigid, leading to blisters if not tied properly.

Summarizing

Finding the right pair of welding boots is crucial for the safety and comfort of beginner welders. The four options mentioned in this article provide different features and benefits to meet the unique needs of each welder.

Whether it’s protection against heat, electrical hazards, or abrasions, each of these welding boots offers reliable performance and durability.

By considering the key features such as insulation, slip resistance, and comfort technology, beginner welders can choose the best welding boot that fits their needs and budget.

Remember to always prioritize safety when working with welding equipment and invest in a pair of high-quality welding boots.

Informational

Millermatic 251 Complete Buying Guide: Used vs New? [Solved]

The Millermatic 251 is a tool that almost all welders are thinking about getting or are already using at work. In the welding community, however, there are a lot of misunderstandings and questions about the Millermatic 251.

In this article, I’ll talk in-depth about the specs of the Millermatic 251, and we’ll also talk about whether you should buy a new or used machine.

Millermatic 251 is a Great Machine in the Right Hands

The Miller company is known for making great welders, and the Millermatic 251 is one of their successful products. It will only work best for you only if you know how to use it.

With 250 Amps at 28 VDC, the Millermatic 251 Mig Welder has the highest output rating in its class.

Digital timers and a big digital control panel on the front of the welder let you change settings like voltage and wire feed speed.

In a single pass, the Millermatic 251 is able to weld materials with thicknesses ranging from 22 gauge all the way up to 1/2 inch.

The Active Arc Stabilizer technology provides excellent starts, and the line voltage compensation provides constant output despite fluctuations in the amount of input power.

The “Auto Gun Detect” function of the machine makes it possible to pull the trigger on the MIG gun, spool gun, or push-pull gun.

If the gun has a timer, the welder will pick it up right away, along with the voltage and the speed of the wire feed.

The Millermatic 251 Mig Welder has a unique flip-down chamber that holds the welder’s parameter chart and other consumables. This lets customers get it right the first time they use it.

Things You Will Get Along with the New Millermatic 251

If you have decidee to buy a new Millermatic 251 then these are a few of the things that you will get along with it for free.

- The power cord and plug (only for the 200/230 V model)

- M-25 MIG gun with a range of 12 feet (3.7 meters) and a capacity of 250 amps for.030/.035-inch wire

- Cable and clamp for working.

- Argon mixture regulator and flow gauge, along with a hose

- Extra contact tips

- reversible drive rolls with running gear and cylinder rack installed from the factory at.030/.035 in.

What Year was the Millermatic 251 Made?

The Millermatic 251 was made in 2005, according to the user manual included with the machine. Miller Industries, on the other hand, does not reveal the machine’s exact production date.

How Many Amps is Millermatic 251?

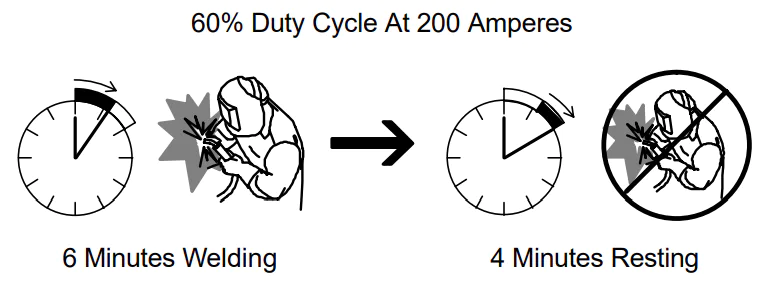

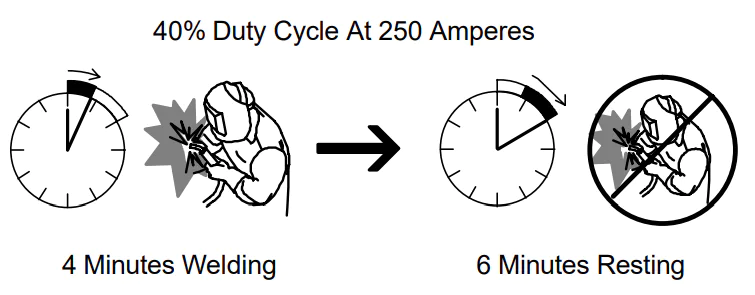

Millermatic 251 has an Amperage range of 30 – 300 Amps. This machine has a duty cycle of 60p% when it is operated at 200 amperes. And if you use it at 250 amps, the duty cycle will be 40%.

[table id= 17/]

How Many Watts is the Millermatic 251?

When working with 28 VDC, the power of the Millermatic 251 ranges from 5600 to 7000 watts. Both 200 amps and 250 amps can be used with this machine.

You can easily figure out how many watts a Millermatic 251 has by multiplying the amps by VDC.

Millermatic 251’s Amps = 200 – 250 Amps

Millermatic 251’s Volts = 28 VDC

Watt Power = Amps X Volts

Watt Power of Millermatic 251 = 200 x 28 = 5600 watts or 250 x 28 = 7000 watts.

Can a Millermatic 251 Weld Aluminum?

Millermatic 251 can be used to weld aluminum, but a Spool gun module is required. The 251 Vintage Millermatic spool gun module employs both flux core (FCAW) and MIG (GMAW) welding.

The following spool guns are compatible with Millermatic 251:

- Spoolmatic 15A

- Spoolmatic 30A

Millermatic 251 Specifications Chart

[table id= 18/]

Millermatic 251 weighs about 98 kg and has dimensions of 32 x 19 x 39 in. It supports solid steel, stainless steel, and flux-cored wires with a wire diameter range of 0.6 to 1.2 mm. It can also work at either a 40% or 60% duty cycle.

Specification image from manual

What is the Duty Cycle of Millermatic 251?

Duty Cycle: The duty cycle is the proportion of 10 minutes that the device can weld at full power without overheating. If the equipment overheats, the thermostat(s) opens, the output stops, and the cooling fan operates. Allow fifteen minutes for the device to cool.

The Millermatic 251 is able to function at a duty cycle of either 60% or 40%. This indicates that the machine can weld for 6 minutes at a current of 200 amperes before needing to rest for four minutes.

whereas at a current of 250 amperes it works for 4 minutes before needing to rest for six seconds.

If the Millermatic 251 begins to overheat, one of two things must happen: either the user must wait fifteen minutes for the machine to cool down, or the user must reduce the duty cycle before restarting the welding process.

Pros of Millermatic 251

- The highest-rated output of all the welders (250 Amps)

- Large digital control panel

- Built-in digital timers

- The voltage compensation feature keeps the power supply constant

- Starts can be smooth with an adjustable run-in period.

- No additional module is needed to connect a Spoolmatic 30A or 15A gun.

- If the welding tip becomes shorted to the work surface, the “Tip Saver” feature will cut power to the welding machine.

- If no arc is detected within three seconds of pulling the gun’s trigger, the weld output will be cut off.

- Automatically adjusting digital thermometers with a fan function

- Heavy-duty, aluminum-casting, dual-gear industrial drive system

Cons of Millermatic 251

- No negative feedback from users, apart from price issues

Is it Worth Buying a Used Millermatic 251?

If you are just starting out in the welding industry and are a novice, you should get a used Millermatic 251 since it will save you money that you can use towards other necessary instruments. However, if you have a successful company and earn a lot of money, you should invest in a modern Millermatic 251, which will save you money on energy and increase the quality of your welds.

Old vs New Millermatic 251: Price Comparison

At the time of writing, a brand-new Millermatic 250 could be purchased on Amazon for $4800. If you wish to purchase a used one, the price might range from $1500 to $2200, depending on the machine’s condition.

[table id= 16/]

Checklist for Buying a used Millermatic 251

When buying a used welder, there are a few things you should look at more closely. You don’t want to add a broken welder to your collection of tools.

- Does it make beads of the same size?

- When the wire is being fed, does it move smoothly or does it slip and jerk?

- Make sure the gas cup is in the right place, the tip is not bent, and there is no slag blocking the wire feed.

- Make sure the size and tension of the wire are right for the driving wheels.

Miller 251 Alternatives

Equipment

New to Welding? Check Out These 6 Machines

Whether you are a DIY enthusiast, a hobbyist or looking to start a new career. Welding is a valuable skill to have. However with so many different types of welding machines available. It can be overwhelming to choose the right one for you.

In this blog post, we will look at 6 of the best welding machines for beginners. Thus Making it easy for you to find the perfect fit for your needs.

List of 6 Best Welding Machines for Beginners

- Hobart Handler 140 MIG Welder

- Eastwood 200 AC/DC TIG Welder

- Hobart 500570 Stickmate 160i Arc Welder

- Weldpro MIG155Gsv Beginner MIG/Stick Arc Welder

- Forney Easy Weld 140FC-I Flux Core Welder For Beginners

- YesWelder MIG-205DS MIG/Flux Core/TIG/Stick Welder

Short Summary

If we compare all 6 welders then in my opinion the Hobart Handler 140 MIG Welder is the best option for beginners. The reason why I say because it is a versatile and reliable machine that is easy to set up and use.

It is capable of welding a wide range of materials and has a compact size and portability which makes it perfect for small projects and repairs.

It also has a variety of features such as an exclusive 3 groove drive roll, built-in contactor and generous operating parameters. which makes it an excellent choice for beginners.

Please keep in mind that this is my own opinion and may vary depending on individual experiences and usage of the product.

1- Hobart Handler 140 MIG Welder

The Hobart Handler 140 MIG Welder is a reliable and versatile machine that is perfect for beginners. It is easy to set up and use.

It is capable of welding a wide range of materials. Its compact size and portability make it ideal for small projects and repairs.

Key Features

- Exclusive 3-groove drive roll for easy switching between small diameter carbon steel MIG wire for exhaust work and auto body applications.

- Built-in contactor and self resetting thermal overload protection for added safety and convenience.

- Flux-Cored and MIG welding capabilities allowing for versatile use in a variety of welding applications.

- Generous operating parameters allowing you to weld thin gauge steel up to 1/4in. steel plate.

- Five position voltage control selector for a smooth stable arc at all welding thicknesses and amperage output of 25-140 Amps.

Specification Table

| Specification | Details |

|---|---|

| Input Voltage & Amperage | Volts: 115, Amps: 25, Max. Amps: 140 |

| Max Weld Thickness | 0.25 in |

| Duty Cycle | 20% at 90A |

| Dimension | 12 x 18 x 24 in |

| Weight | 66.0 lbs |

| Warranty | 12 months parts / 12 months labor |

Note: The list of Pros and Cons provided are based on user reviews found on the product page and may vary depending on individual experiences and usage of the product.

2- Eastwood 200 AC/DC TIG Welder

The Eastwood 200 AC/DC TIG Welder is a high performance machine that is ideal for welding both aluminum and steel.

It is perfect for beginners who want to learn TIG welding because it is easy to use and has a wide range of adjustable settings.

Key Features

- Dual voltage capability allowing for operation on either 110vAC, 15-amp circuit or 220vAC, 30-amp circuit.

- 1/4″-thick welding capacity on 220VAC.

- High-frequency start for precise arc control and square-wave inverter for accurate aluminum welding.

- Flex Head WP-17-type torch that accepts common cups and collets with up to 1/8″ electrodes and also a Gas lens kit to greatly improve your fabrication skills

- Rocker Style foot pedal with machine mounted controls and flow meter gauge for improved gas flow control and quick repeatable flow adjustments.

Specification Table

| Specification | Details |

|---|---|

| Input Voltage | 120vAC or 240vAC |

| Amperage | TIG: 10-190 amps, Stick: 10-185 amps |

| Duty Cycle | TIG: 60% at 190 amps and 100% at 143 amps Stick: 60% at 185 amps and 100% at 143 amps |

| Dimensions | 17.8” x 8.4” x 20.20” |

| Weight | 38 lbs |

| Warranty | 3 Years |

3- Hobart 500570 Stickmate 160i Arc Welder

The Hobart 500570 Stickmate 160i Arc Welder is a powerful and versatile stick welding machine that is perfect for beginners. It has a wide range of adjustable settings which makes it easy to use. It is also capable of welding a variety of materials.

Key Features

- Dependable, reliable, and rugged design for long-lasting use.

- Lightweight and portable design with a weight of under 20 lbs, making it easy to carry and store.

- Quick and easy starts with hot start technology.

- High output of up to 160A for welding up to 5/32 inch mild steel.

- Dual voltage input power of 120V/240V for easy connection to both 120 and 240V receptacles without the need for additional tools.

Specification Table

| Specification | Description |

|---|---|

| Input Voltage & Amperage | 240 Volts |

| Max Weld Thickness | Not specified |

| Duty Cycle | Not specified |

| Dimension | 13.38 x 7.13 x 10.5 inches |

| Weight | 15 pounds |

| Warranty | 5/3/1 Industrial Use |

4- Weldpro MIG155Gsv Beginner MIG/Stick Arc Welder

The Weldpro MIG155Gsv Beginner MIG/Stick Arc Welder is a versatile machine that is perfect for beginners. It is easy to set up and use. It can be used for both MIG and stick welding. It is also capable of welding a wide range of materials.

Key Features

- Dual Input Power Capability: This welder has the ability to select between 120-volt input power for home and generator-driven environments or 230-volt input for shop applications with thicker materials.

- Complete Package: The welder comes complete as pictured, ready for use.

- Wide Welding Range: With a welding range of 30 to 155 amps, this welder can handle a variety of welding tasks.

- Versatility: This welder can handle MIG, flux-cored and stick welding, allowing for a wide range of welding capabilities.

- Adjustable Settings: With the ability to feed wire at 78 inches to 396 inches per minute and infinitely adjustable wire speed and heat settings, this welder offers precision and control for your welding projects.

Specification Table

| Specification | Value |

|---|---|

| Input Voltage & Amperage | 115V/230±15%, 30 to 155 Amp |

| Max Weld Thickness | 1/4 inch mild steel |

| Duty Cycle | Not specified |

| Dimension | 14.96 x 13.58 x 6.69 inches |

| Weight | 21.2 pounds |

| Warranty | 3 Years |

5- Forney Easy Weld 140FC-I Flux Core Welder

The Forney Easy Weld 140FC-I Flux Core is a reliable flux core welding machine. It is perfect for beginners who want to learn flux core welding because it has a wide range of adjustable settings and it is capable of welding a variety of materials same as others.

Key Features

- EASY TO USE: This machine is ideal entry-level welder with infinite voltage and wire feed speed control for perfect welds every time.

- POWERFUL: 140 AMP output allows for welding up to 1/4″ of mild steel with protection from an all-metal case.

- PORTABLE: Only weighs 19 lbs., it is easily portable for any DIY project, maintenance and repair job, garage and more!

- FLUX-CORE WELDING: Uses .030″ flux-core wire and doesn’t require gas, can run on standard household power with at least a 20 AMP breaker.

- DIMENSIONS: 16.75″ (425.45 millimeters) x 8.125″ (206.38 millimeters) x 12″ (304.8 millimeters)

Specification Table

| Specification | Detail |

|---|---|

| Input Voltage & Amperage | 120V |

| Max Weld Thickness | 1/4″ of mild steel |

| Duty Cycle | 30% @ 90A |

| Dimension | 16.7 x 12 x 8.1 inches |

| Weight | 19 pounds |

| Warranty | 12 month |

6- YesWelder MIG-205DS MIG/Flux Core/TIG/Stick Welder

The YesWelder MIG-205DS MIG/Flux Core/TIG/Stick Welder is a versatile and powerful machine which is perfect for beginners.

It is capable of welding a wide range of materials and can be used for MIG, flux core, TIG and stick welding. It also has a wide range of adjustable settings which makes it easy to use for beginners

Key Features

- MIG Function: Synergic Controlled on MIG function for very easy and simple operation.

- 4 in 1 Functionality: Four functions in 1 of Gas MIG /Gasless MIG / Lift TIG / Stick

- Wire Compatibility: Takes up to 0.9mm(.035″) MIG solid wire(Gas MIG) and 0.9mm(.035″) MIG Flux wire(Gasless MIG)

- MIG Roll Compatibility: Apply to D100/D200 rolls (<10lbs) of MIG wire

- Amp Rating: 200 Amp Gas/Gasless MIG welder with a 50 Amp plug(220V) and 160 Amp Gas/Gasless MIG welder with a 35 Amp plug(110V).

Specification Table

| Specification | Value |

|---|---|

| Input Voltage & Amperage | 110V/220V 50/60 Hz |

| Max Weld Thickness | Not specified |

| Duty Cycle | @110V, 60%@160A, 100%@123A @220V, 60%@205A, 100%@158A |

| Dimension | 18.11″*8.07″*14.17″ |

| Weight | 23lb |

| Warranty | Not specified |

Conclusion

Selecting the right welding machine can be a daunting task for beginners but with the right information and research it can be a smooth process.

These six above mentioned machines are some of the best options available in the market . They are reliable, easy to use and versatile machines that can cater to a wide range of welding applications.

We hope this blog post has helped you in your search for the perfect welding machine. Happy welding.